As my research is about reservoir simulation, it would be good to go over the fundamentals of the standard reservoir simulation. What is it? Why people need it? What are its key physical principles that reservoir simulation is based on? What are the uses of it? It is important to understand those basics before using it. And it is even more important to present it in a fun and simple way!

Basics

Why do we need simulation? Essentially, we want to better take control of something. A model is a replica of the reality with respect to things that you are working on. You simulate the actual practice by playing around with the model. Just like to simulate the actual horse-riding using a horse simulator, or to practice outdoor rock climbing using the artificial climbing wall in the gym! All types of movements needed in outdoor climbing can be learned at the gym.

To consider the simulation practically, the model used in the simulation should be cheap, easy to control, and highly customizable. To use rock climbing as the example, building a climbing wall in the gym is much cheaper and more convenient than traveling to the natural cliff far away. You don’t want to try some kind of new movement on a high cliff where the protection is dubious (Ahhhhh…!). However, you can safely do it in an indoor climbing wall. Moreover, you can create different scenarios by simply adjusting the angle or changing the holds on the wall. These are the advantageous of the simulation and the model. Likewise, managers need to deal with million- even billion-dollar asset, it would be good to play around different ideas in the cheap sandbox — that is how reservoir simulation comes into play.

Engineering Oil & Gas underground

In O&G industry, people earn money by extracting natural resources from the underground. Petroleum reservoir, the underground formation containing oil & gas, becomes the focus of our study (who? we petroleum engineers! reservoir engineer in specific). It is extremely complex and difficult to describe the reservoir without a good amount of uncertainty. The two main reasons are: 1. it is in the underground, you can not see it and measure properties directly; and 2. it is formed by natural deposition combined with very complicated geological processes (wind, river, ocean, etc.), it is not made from a factory by modern technology. Even the geometric extent of the reservoir is very complicated to describe.

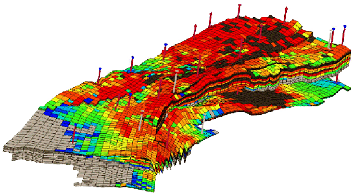

A reservoir model contains the permeable rock formation of our interest. Here the color specifies the oil saturation (more red, more oil).

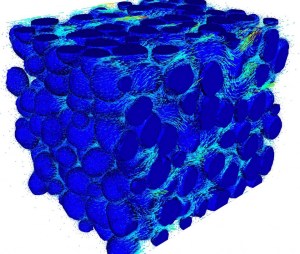

While reservoir engineers talk about so many different kinds of parameters, such as permeability, porosity, viscosity, compressibility, relative permeability, etc., it is crucial to remember that the fundamental process occurring in the reservoir is the so-called “fluid flow in porous media“. Fluids (hopefully oil, not too much water) are flowing through the permeable rock, reaches the well bore, then flow to the ground through the pipes.

In engineering the reservoir, there are two most important variables that we should bear in mind: pressure and saturation.

Pressure is the very reason that fluids can flow, it is the driver of the flux. Because there is a high pressure underground, oil can flow to the ground easily. So, in practice, we don’t want the reservoir pressure drops too much, otherwise, the fluids in the reservoir will have less and less energy to flow to the surface. However, that is how people exploit oil fifty years ago. They simply let oil flow, and use pump to pump oil out when pressure becomes low (so-called “primary depletion”).

Saturation is a quantity to indicate what is inside of the porous space. It is defined as the volume fraction of oil/water/gas in pore space. Typically, a good oil reservoir has an oil saturation of about 80%, and a water saturation of about 20%, which means 80% of the pore space inside the rock is occupied by oil, the other 20% is occupied by water (so-called “connate water”).

Pressure and saturation are two main variables of our interest. Other reservoir engineering quantities are also important, but they are static properties. They don’t change very much. Those properties include:

- Rock properties: porosity, permeability, heterogeneity

- Fluid properties: viscosity, PVT property

- Rock-fluid properties: relative permeability, capillarity

- Initial conditions and boundary conditions (aquifer support, etc.)

Fundamental principles

One of the beauties of the modern science lies in the ability to derive numerous complicated phenomena from only few basic principles. For example, the Newtonian laws of mechanics have explained the apparently very complicated celestial body movements, as well as the free falling on the ground. In reservoir simulation, the two main governing principles are: the material balance and the Darcy’s law. One may optionally add the isothermal fluid phase behavior if the phase behavior requires more detailed modelling.

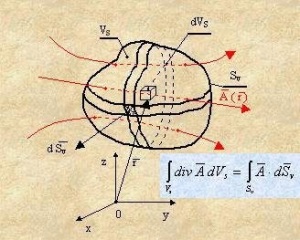

First, material balance talks about the conservation of materials. It means, the oil being produced on the surface are not from nowhere. To be more precisely, the principle of material balance is: given a specific volume V (called control volume), for any component, the net mass increase must be equal to the mass change of this component inside this control volume, namely

.

In particular, our conservation law is expressed in terms of flux (from/to adjacent region), accumulation (mass change inside the volume), and source/sink (production/injection well).

Second, the Darcy’s law deals with the relationship between the pressure and the fluid flux. Imagine a fluid flow through a porous medium (such as a pack of sand) of length L and sectional area A. The Darcy’s law can be illustrated as a relationship between the flow rate Q, length L, sectional area A, pressure drop (pa–pb) as well as the fluid viscosity and rock permeability, namely

.

In writing the governing equations of reservoir simulation, the Darcy’s law is usually written in terms of flux and pressure gradient.

Then, phase behavior is about how a mixture of chemical components (usually, for example, C1 up to C30, CO2, H2O) is separated into several phases at certain pressure and temperature. While it is easy and obvious to think from ordinary experience that how oil/water/gas are separated, but the same process can be very complicated when you have a changing high pressure and high temperature situation. More and more gas will be dissolved in the oil phase as the pressure goes up, and finally become one single phase at the so-called “bubble point pressure”. Oil can exist in vapor phase, too. Liquid and vapor phases have different component percentages. So, phase behavior is not trivial. But, in many simple case, we simplify the situation into the so-called “Black-oil model”, where the phase behavior is simplified into a table of numbers called solution-gas-ratio (and maybe also with the vaporized-oil-ratio), or even “Dead-oil model” or “Dry gas model”, where hydrocarbon only forms one phase. In any cases, water is considered always separated from oil and gas phase.

Integrate all information together

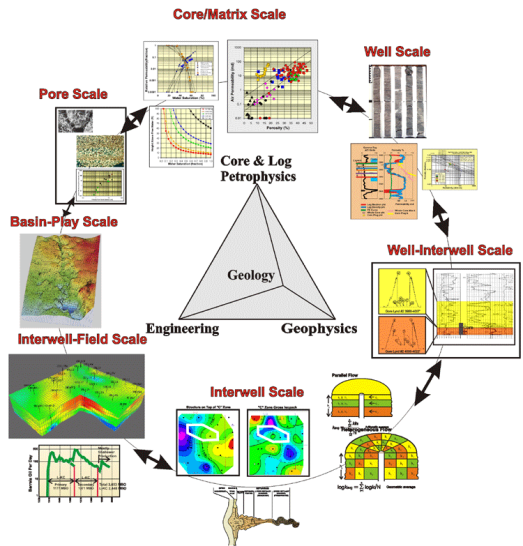

Once we have the governing physics, we can build the reservoir simulation model by filling up with all other detailed information, including rock properties, fluid properties, reservoir initial and boundary conditions, etc. A reservoir simulation model is a distillation of a huge amount of data from many different studies. And that is by no means simple.

- Geologists provide the geological information, including reservoir extent, rock type, heterogeneity details, layering of the formations, the presence of faults and fractures, etc.

- Geophysicists provide mainly the seismic data and its interpretation, from which more detailed information about rock properties, fluid properties can be obtained on a large scale.

- Well logging and well testing specialists provide detailed information from the existing wells being drilled (so it is on a smaller scale).

- PVT lab experiments offer information for reservoir fluids, such as their chemical components, physical properties.

- Reservoir modelers integrates all information together and make reasonable decisions on how to build the reservoir model, such as, what data source to choose, how to resolve a conflict of data when there is one.

- History matching processes incorporate existing production data (if they exist), and update the reservoir model in a reasonable way. Hence, we can keep improving the quality of reservoir model as production goes.

Uses of reservoir simulation

There are many ways to use the reservoir simulation. Here is some excerpt from the “Notes on Reservoir Simulation” by Khalid Aziz, Louis Durlofsky, and Hamdi Tchelepi from Stanford University:

- Increase profitability through improved reservoir management

- Assess economic and technical risks through sensitivity studies

- Enhance credibility with third parties

- Predict consequences of reservoir development and management decisions

- Monitor reservoir performance and assist in reservoir/well control

- Respond to safety, environmental and regulatory concerns

- Improve communication among interested parties

- Train engineers and operators

- Assess the impact on ultimate recovery of changing to a different EOR scheme

- Optimize well location and well completion

- Assess possible advantages of horizontal, multilateral or other non-conventional wells over vertical wells

- Troubleshooting

- … …

Although the list can be very long, but these application can be summarized from three main aspects:

- Data integration: building reservoir simulation model involves reviewing data from all different resources. It would be a valuable opportunity to check the correctness and consistency of the data, and generate an “overview” of the reservoir.

- Production predictor: simulation runs give the prediction of the reservoir performance. We all care about how much money we gonna make, no?

- Decision making tool: information offered by the simulation will help people making decisions on various engineering or economical issues.

Hopefully, you will now have some basic ideas of the reservoir simulation. Thanks for reading!

Thank you. I am an undergraduate student and currently doing my dissertation on reservoir simulation. I am also interested to do my higher study on reservoir engineering. Your blog is of great benefit to me. Can you please continue with the writing and exploring reservoir simulation more.

LikeLike

Thanks I will try to write more! And your feedback is very helpful!

LikeLike

Pingback: Reservoir Simulation – Petro Prophet: Oilfield Education

Great summary of reservoir simulation.

LikeLike